PRODUCTS

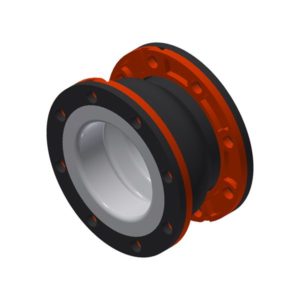

Rubber Expansion Joints

Rubber expansion joints are designed to relieve mechanical stressors; they can be made from many materials including stainless steel, Polytetrafluoroethylene, and braided flexible metal. Rubber expansion joints are particularly beneficial due to its flexible nature, which makes them suitable for many functions, including the absorption of sound, thermal energy, and shock. Foster Hose and Fittings’ Proco rubber expansion joints are specifically designed to reduce the need for maintenance, repair, and manual assistance.

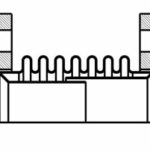

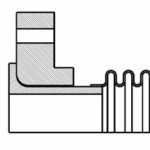

Proco Style 231 / 221 Single Wide Arch

Proco Style 231 single wide arch rubber expansion joints are built to withstand even the most rigorous piping system configurations. They are single wide-arch products, specifically constructed to reduce or eliminate common occurrences such as noise and vibration, misalignment/offset, or turbulence. Style 231 expansion joints are appropriate for a wide variety of industrial applications, and are available in open arch and filled arch configurations.

Features

Features

- Absorption of Directional Movement

- Less Turbulence or Material Entrapment

- Absorption of Vibration, Noise, and Shock

- Compensation for Misalignment

- Wide Range of Service and Lighter Weight

- Easy Material Identification

231-BTPTFE Lined

Next-generation API Bottom Loading Couples combines ease of maintenance with a unique spring-loaded sleeve design to deliver the ultimate coupler experience.

- 5 Cam Design: Easy alignment, tight adaptor connections and side-force resistance during loading

- Dual Interlocks: Ensure that opening cannot occur unless properly connected to an API Adaptor

- Superior Sealing: Simple, reliable smart-seal design with dual high-performance O-rings

- High-Performance Seals: Special Fluorocarbon Seal Compound for compatibility across most products, including gasoline, diesel, biodiesel and ethanol*

- Maintenance: Pins and small threads eliminated to provide quick, easy access to critical components; nose seal replaced without requiring removal of coupler from rack; no special tools required; complete rebuild in minutes

- Spring-Loaded Sleeve: Unique sleeve design automatically “jumps” onto API truck adaptor

- Operation: Stainless-steel “ergo” handle design for easy, smooth operation

*-Other seals available upon request.

Technical

Design Parameters

| Max Design Pressure | 125 psi (g), 8.6 bar (g) |

| Max Allowable Working Pressure | 75 psi (g), 5 bar (g) |

| Max Flow Rate | 600GPM, 135 M3/H |

| Max Temperature | See seal options |

| Weight | 18.5 lbs (8.39 kg) |

| Pressure Drop (At Max Flow Rate) | 2-5 psi (g), .24 bar (g) |

Materials

| Body, Sleeve, Poppet | ASTM B26 Anodized (Aluminum A356-T6) |

| Cam | ASTM A351 CF8M (316 SST) |

| Cylinder | ASTM SB241(Aluminum 6061-T6) |

| Shaft | ASTM A564 (13-8 Condition RH 950 SST) |

| Seals | See Seal Options |

| Clevis Pin | ASTM SA564 (17-4 PH SST, H900 Hardened) |

Seal Options

| Seal Material | Coupler Model # | Nose Seal (16) | Stuff Box Seal (26) | Stuff Box Seal (27) | Cylinder Seal (15) | Temp. Rating |

|---|---|---|---|---|---|---|

| Buna | 1004D4-0401 | H30482M | H20129M | H31705M | H30258M | -20°F - 212°F (-29°C - 100° C) |

| Fluorocarbon | 1004D4-0402 | H30483M | H20175M | H31706M | H30217M | -20°F - 400°F (-29°C - 204° C) |

| EPT | 1004D4-0404 | H31957M | H20176M | H31707M | H31956M | -50°F - 225°F (-46°C - 107° C) |

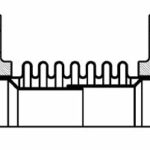

Proco Style 233 Expansion Joints

Proco Style 233 expansion joints are built to withstand even the most rigorous piping system configurations. They are triple wide-arch products, specifically constructed to reduce or eliminate common occurrences such as noise and vibration, misalignment/offset, or turbulence. Style 233 expansion joints are appropriate for a wide variety of industrial applications, and are available in open arch and filled arch configurations.

Technical

Features

- Absorption of Directional Movement

- Less Turbulence or Material Entrapment

- Absorption of Vibration, Noise, and Shock

- Compensation for Misalignment

- Wide Range of Service and Lighter Weight

- Easy Material Identification

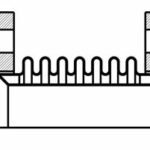

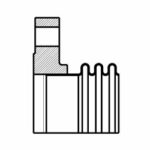

Proco Style 232 Rubber Expansion Joints

Proco Style 232 rubber expansion joints are built to withstand even the most rigorous piping system configurations. They are double wide-arch products, specifically constructed to reduce or eliminate common occurrences such as noise and vibration, misalignment/offset, or turbulence. Style 232 expansion joints are appropriate for a wide variety of industrial applications, and are available in open arch and filled arch configurations.

Features

Features

- Absorption of Directional Movement

- Less Turbulence or Material Entrapment

- Absorption of Vibration, Noise, and Shock

- Compensation for Misalignment

- Wide Range of Service and Lighter Weight

- Easy Material Identification

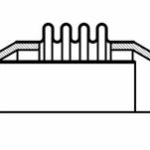

Proco Style 271 Rubber Expansion Joint

The Proco Style 271 rubber expansion joint is a single super-wide flowing arch design. The wide flowing arch of the Proco Style 271 is self-cleaning, which eliminates the need for a filled arch design and makes it the perfect choice for slurries.

The Style 271 can replace and be interchanged with hand-built narrow/wide arch, molded wide arch, and spherical type expansion joints.

Features

Features

- Absorption of Directional Movement

- Reduced Turbulence or Material Entrapment

- Absorption of Vibration, Noise, and Shock

- Compensation for Misalignment

- Wide Service Range and Lighter Weight

Mercer Rubber Series 700

The Series 700 features either a TFE* or FED** seamless liner that extends through the body of the expansion joint to the outer edge of raised flange faces. The liner is fused to the body when the joint is cured. This type of construction provides ultimate protection against chemicals seeping or leaking. An optional coat of Hypalon paint is recommended to protect the exterior against weather, ozone and chemicals.

Features

Features

- Working pressures up to 165 PSI at temperatures up to 400°F in standard models.

- Minimum 4:1 safety factor, rated to burst pressure

- Teflon liners are etched and permanently bonded to expansion joint body and flanged faces

- Components are pressured cured resulting in structurally sound, long service life.

- Optional exterior coat of Hypalon paint provides additional protection against ozone weathering and chemical exposure

- Handbuilt to your exact specifications

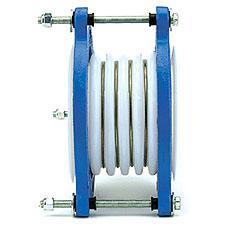

Resistoflex® PTFE Expansion Joints

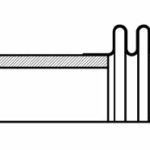

Resistoflex® 2-Convoluted Expansion Joints

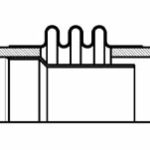

Resistoflex® 3-Convoluted Expansion Joints

Resistoflex® 5-Convoluted Expansion Joints

Resistoflex 2-convolute expansion joints are contour molded of TEFLON® PTFE by a patented process. They are corrosion resistant, non-aging, with extraordinary flex life and reliability. The flexible element is formed over the full sealing face of the end flanges eliminating troublesome separate gaskets.

Resistoflex R-Series 3-convolute expansion joints are contour molded of Teflon® T-62 PTFE by a patented process. R-Series expansion joints use limit bolts to control overextension during expansion, and NITRONIC 50 reinforcing rings. Wrap around safety shields are specifically designed to provide sprayout protection and are required in hazardous service.

Resistoflex 5-convolute expansion joints are contour molded of TEFLON® PTFE by a patented process. They are corrosion resistant, non-aging, with extraordinary flex life and reliability. The flexible element is formed over the full sealing face of the end flanges eliminating troublesome separate gaskets.

Contact Us

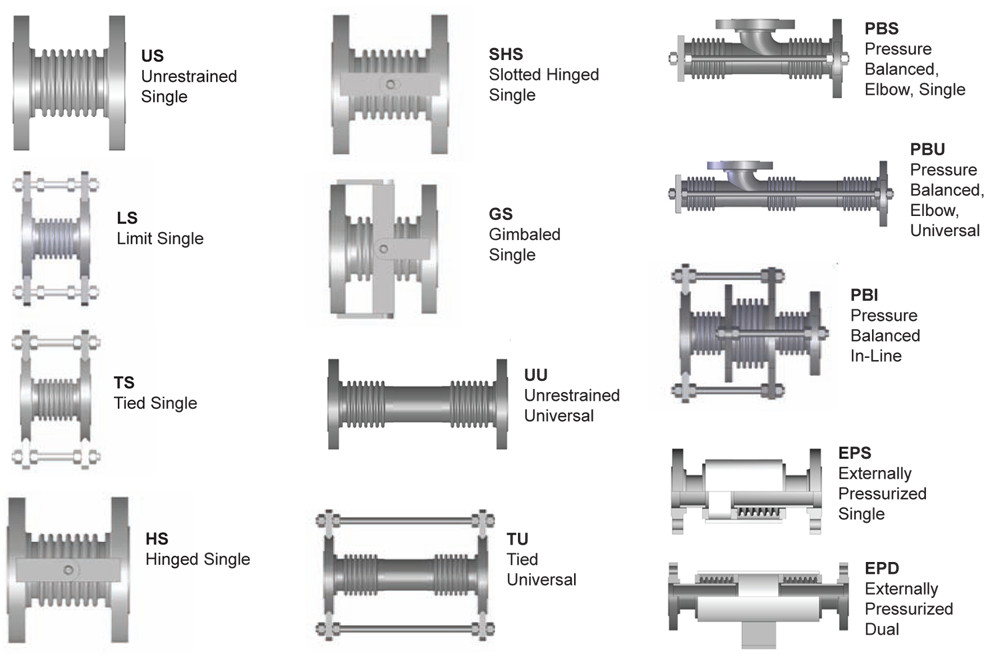

Metal Expansion Joints

Foster Hose and Fittings is proud to distribute quality products like Hose Master’s line of expansion joints. Designs conform to EJMA and ASME Section VIII, meeting the requirements of the piping, boiler and pressure codes – B31.1 and B31.3. This certification applies to the scope of activity related to the fabrication and assembly of pressure piping, which means our engineering and production teams can design systems in accordance with the rules of the ASME Boiler and Pressure Vessel Code. This certification gives Hose Master the “U”, “PP” and “R” Stamps for expansion joints.

Designs

Connections

BB – Banded Bellows

Ideal for slipping over pipe and welding in place

WE – Welded End

Beveled to facilitate pipe-to-pipe welding. Most common end connection.

FF – Fixed Flange

Recommended for ease of replacement. Requires accurate flange hole alignment.

VF – Vanstone Flange

Economical solution for piping systems with misaligned bolt holes.

LJ – Lap-Joint Flange

Commonly used when vanstone flanges are not an option.

Internal Liners

SW – Single Welded Liner

Most common type of internal liner. Maximum durability.

TW – Telescoping Welded Liner

For large axial movements.

FW – Flush Welded Liner

No protrusion into flow-stream. Minimal pressure drop. Recommended for refactory-lined pipe.

SD – Single Drop-In Liner

Can be removed and cleaned.

TD – Telescoping Drop-In Liner

For large axial movements. Can be removed and cleaned.