Industry Leader in Industrial Hose Production

Industry Leader in Industrial Hose Production

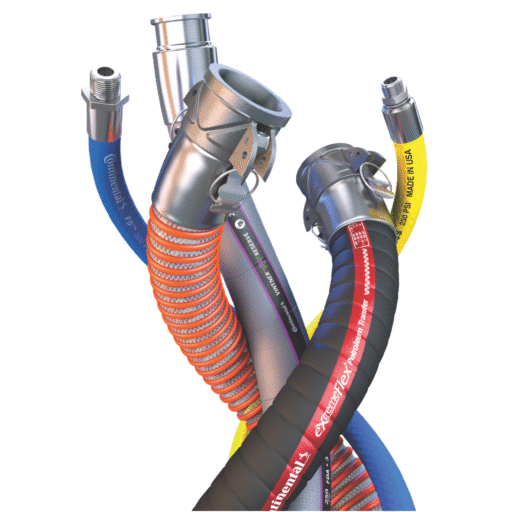

At Foster Hose & Fittings, we build industrial-grade solutions you can trust. As a recognized leader in hose production, we provide reliable products, fast turnaround, and experienced support to industries that can’t afford downtime.

With one of the largest inventories in the U.S. and decades of fabrication experience, we deliver custom and premade hose assemblies for applications in chemical transport, oil & gas, power generation, food processing, and heavy equipment.

We manufacture and assemble:

Chemical Hoses – Including UHMW, PTFE, and composite options for aggressive media

Sanitary & Food Grade Hoses – 3-A certified assemblies with FDA-approved materials

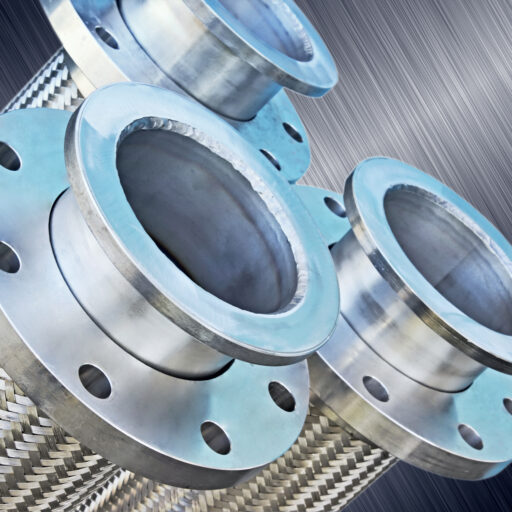

Metal & PTFE Hoses – Built in-house for high-temperature or extreme environments

Specialty Hoses – From sandblast to steam and pressure washer hose

Why Foster Leads in Industrial Hose Production

In-House Fabrication: We make what we sell. Industrial hose assemblies, metal hose, and custom gaskets—done in-house and done right.

Safety First: All hoses are pressure tested and documented. For full lifecycle tracking, ask about our OnGuard™ program.

Same-Day Availability: Need it now? We keep thousands of feet of hose and hundreds of fittings on-hand and ready to ship.

Expert Support: NAHAD-certified staff and field specialists help you spec and build hose assemblies that match your exact application.

Compliance Ready: We meet and exceed standards for FDA, USDA, 3-A, DOT, and MSHA where applicable.

FAQs

What types of industrial hose does Foster Hose & Fittings produce?

We produce and assemble a wide range of hose types including hydraulic, chemical, food-grade, metal, steam, pressure washer, and specialty hoses. Each hose is built to meet specific temperature, pressure, and media requirements.

Do you offer custom hose assemblies?

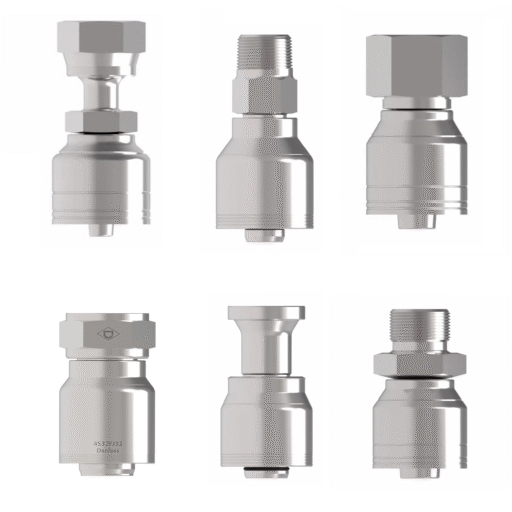

Yes. All hose assemblies can be customized to your application. We offer in-house crimping, testing, tagging, and can build hoses to meet industry-specific standards including FDA, 3-A, DOT, and more.

What is hose crimping, and why is it used?

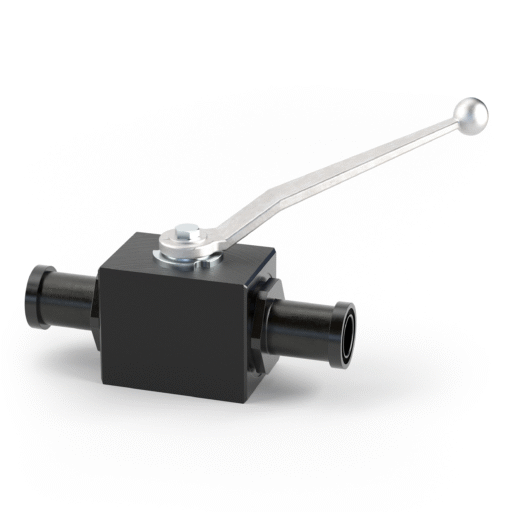

Hose crimping uses a machine to compress a metal sleeve around a hose and fitting, creating a permanent, leak-proof seal. It’s standard in high-pressure and high-risk environments.

How does crimping compare to clamping?

Crimping provides a stronger, more reliable connection. Unlike clamps that can loosen or shift, crimped assemblies stay secure under pressure, vibration, and extreme conditions. Clamping can work for low-pressure, non-critical uses or temporary fixes. But for most industrial applications, crimping is safer and lasts longer.

How fast can I get my hose order?

Most assemblies are available for same-day or next-day shipping, depending on stock. We keep a large inventory of bulk hose and fittings on hand so we can build and ship fast—no waiting on backorders or drop-ships.”