INDUSTRIAL PRODUCTS ARE OUR WORLD!

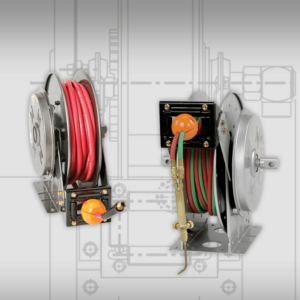

Foster is a specialty distributor of industrial hose, fittings, and related components, as well as a light assembler of those products. This involved both the distribution of the products from the manufacturers we represent and light assembly work.

The assembly work consists of customizing a product to a customer’s requirements. The vast majority of this work is the fabrication of air, hydraulic, fuel, chemical, pharmaceutical, food, and other industrial hose assemblies.