In food production facilities, preventing cross-contamination isn’t just a best practice—it’s a critical safety requirement that protects consumers and your business. One of the most effective strategies for maintaining food safety is implementing a comprehensive color-coding system throughout your facility. This approach creates visual barriers that help prevent the mixing of different food types, allergens, and cleaning materials.

Why Color-Coding Matters in Food Safety

Cross-contamination occurs when harmful bacteria, allergens, or other contaminants transfer from one food product to another. This can happen through direct contact, shared equipment, or improper handling procedures. The consequences can be severe, including foodborne illness outbreaks, product recalls, costly shutdowns, and permanent damage to your brand reputation.

Color-coding serves as a simple yet powerful visual management system. When properly implemented, it creates clear boundaries between different areas, processes, and products in your facility. Team members can quickly identify which equipment belongs where, reducing the risk of accidentally using the wrong hose, tool, or cleaning supply in the wrong area.

Essential Applications for Color-Coding Systems

Washdown Hose and Equipment

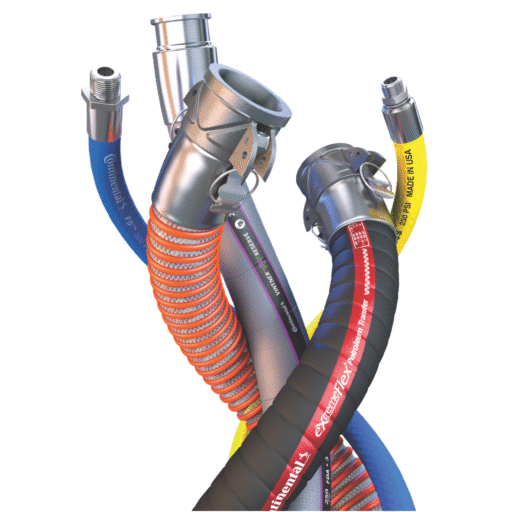

Premium washdown hoses represent one of the most important applications for color-coding. Different colored hoses should be designated for specific areas or functions:

- White hoses for dairy processing areas

- Blue hoses for fish and seafood preparation

- Red hoses for meat processing zones

- Yellow hoses for poultry handling areas

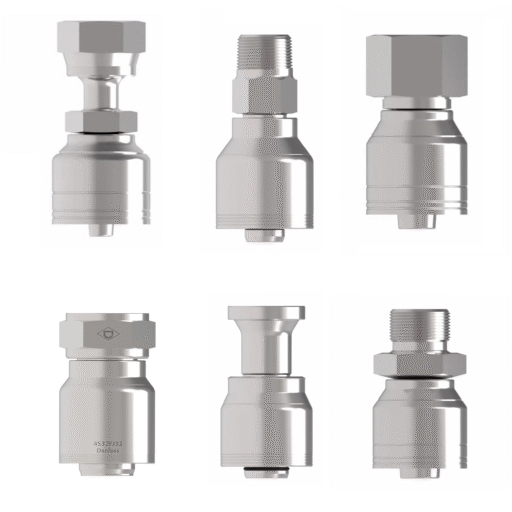

Foster Hose & Fittings offers washdown hoses in multiple colors with premium wrapped cover options. Our food-grade assemblies feature permanent crimp end connections and can withstand temperatures from -20°F to 200°F, making them ideal for demanding food production environments.

Sanitary Hose Systems

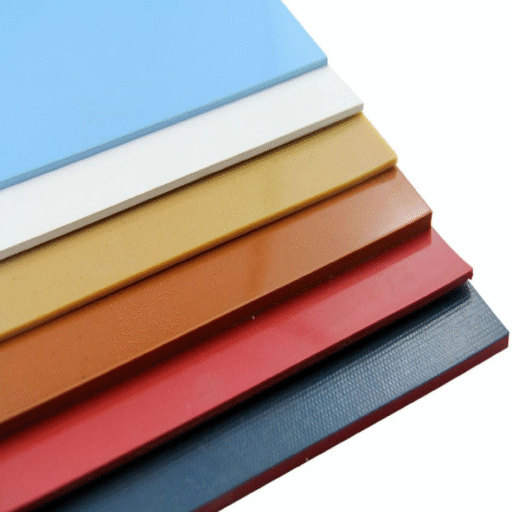

Sanitary hose assemblies used for product transfer should also follow strict color-coding protocols. Our RubberworxTM sanitary hoses are available in six different colors: white, gray, red, blue, green, and orange. This variety allows for quick visual identification while maintaining FDA compliance and 3-A sanitary standards.

The color-coding helps prevent situations where a hose used for dairy products might accidentally be connected to a line handling nut-based ingredients, protecting consumers with allergies and maintaining product integrity.

Spray Nozzles and Accessories

Even spray nozzles should follow your color-coding system. Our premium spray nozzles are available in white, black, red, blue, and gray options. Each color can be assigned to specific cleaning tasks or areas, ensuring the right nozzle is used for the right application every time.

Implementing an Effective Color-Coding Strategy

Planning Your System

Start by mapping out your facility and identifying different zones based on:

- Product types (dairy, meat, poultry, seafood, produce)

- Allergen categories (nuts, dairy, gluten, shellfish)

- Processing stages (raw materials, work-in-progress, finished products)

- Risk levels (high-risk ready-to-eat foods vs. lower-risk items)

Training and Documentation

Your color-coding system is only effective if everyone understands and follows it. Create clear documentation that includes:

- Color assignments for each area and product type

- Proper cleaning procedures for each colored item

- Storage requirements to prevent mixing

- Consequences of not following the system

Regular training sessions should reinforce these protocols and address any questions or challenges that arise.

Equipment Storage and Organization

Designated storage areas for each color category prevent accidental mixing. Install clearly marked hooks, racks, and storage bins that match your color-coding system. This visual organization makes it easy for team members to return equipment to the correct location and grab the right items for their tasks.

Material Handling and Anti-Static Solutions

For facilities handling dry ingredients, anti-static hoses play a critical role in both safety and contamination prevention. Static electricity can attract dust and particles, potentially contaminating products or creating fire hazards with flammable materials.

Our Kuriyama anti-static material handling hoses are available in different configurations and can be integrated into your color-coding system. The Kuriyama 2020 features a transparent polyurethane construction that allows visual product inspection while maintaining FDA compliance. Different colored accent bands or fittings can distinguish between lines handling different ingredients.

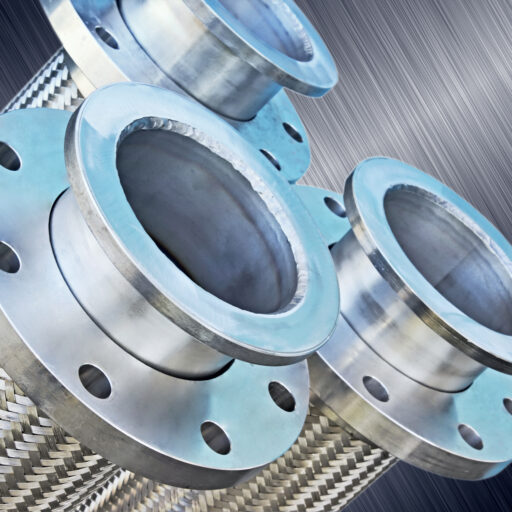

Premium Chemical Resistance for Cleaning Applications

Food production facilities use various cleaning chemicals and sanitizers throughout the day. Premium PTFE hoses designed for chemical applications should also follow color-coding protocols to prevent mixing incompatible chemicals or accidentally using the wrong cleaning solution in food contact areas.

Our TUFLUOR® PTFE chemical hoses feature chemical-resistant covers and can handle temperatures from -40°F to +302°F. By incorporating these into your color-coding system, you ensure that cleaning chemicals stay in their designated areas and never come into contact with food products.

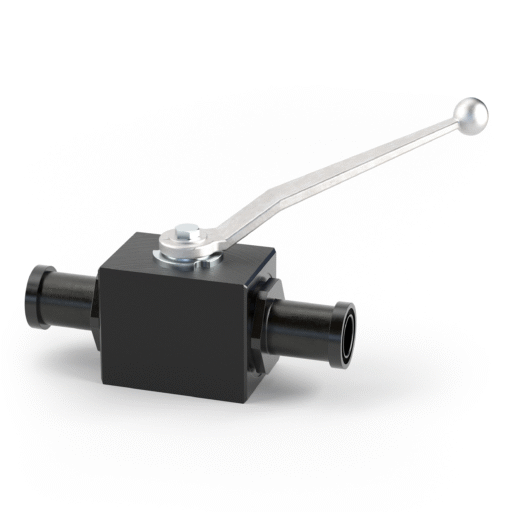

Mixing Stations and Temperature Control

Steam and cold water mixing stations should incorporate color-coding in their hose connections and accessories. Different colored hoses can indicate water temperature ranges or specific cleaning applications. Our thermostatically controlled mixing stations come with automatic safety features and can be equipped with colored washdown hoses to match your facility’s system.

Inline Magnets and Product Protection

Metal detection and removal systems also benefit from color-coding. Our inline magnets for vacuum systems are available in different sizes and can be marked or fitted with colored indicators to show which product lines they protect. This prevents magnets designed for one type of ingredient from being accidentally installed in lines handling different products.

Quality Assurance and Compliance Benefits

A well-implemented color-coding system supports regulatory compliance and quality assurance programs. During inspections, auditors can quickly verify that proper separation protocols are in place. The visual nature of color-coding makes it easy to demonstrate your commitment to food safety.

Documentation becomes simpler when you can reference specific colored equipment in your procedures and incident reports. If an issue arises, you can quickly trace which colored systems were involved and take appropriate corrective actions.

Cost-Effective Implementation

While implementing a color-coding system requires upfront investment in equipment, the long-term benefits far outweigh the costs. Preventing even one contamination incident or product recall can save thousands of dollars in lost product, cleanup costs, and reputation damage.

Foster Hose & Fittings provides complete color-coded solutions including hoses, fittings, nozzles, and accessories. Our bulk purchasing options and custom assembly services help keep implementation costs manageable while ensuring you get exactly what you need for your specific facility.

Maintenance and Replacement Planning

Your color-coding system needs ongoing maintenance to remain effective. Establish schedules for:

- Regular inspection of colored equipment for wear or fading

- Replacement of items that no longer clearly display their assigned colors

- Deep cleaning procedures that don’t damage color indicators

- Updates to the system as your facility or processes change

Frequently Asked Questions

A: The number of colors depends on your facility’s complexity. Most operations work well with 4-6 colors, but larger facilities with multiple product lines may need more. The key is having enough colors to maintain clear separation without creating confusion.

A: Faded or unclear colors compromise your system’s effectiveness. Establish replacement schedules based on usage patterns and environmental conditions. Our premium washdown hoses are designed with fade-resistant covers to maintain color clarity longer.

A: Yes, existing equipment can often be retrofitted with colored tape, bands, or covers. However, permanent solutions like colored hoses and fittings provide better long-term reliability and professional appearance.

A: Mobile equipment should either be assigned to the highest-risk zone it enters or follow strict cleaning protocols between uses. Consider dedicating separate equipment to each zone when possible.

A: Your color-coding system should be simple enough that temporary workers can understand it quickly. Provide visual guides and brief training sessions for all temporary staff.

Implementing a comprehensive color-coding system transforms food safety from a complex challenge into a manageable, visual process. When combined with quality equipment from Foster Hose & Fittings, your color-coding strategy becomes a powerful tool for protecting products, consumers, and your business reputation. Contact us today at (314) 947-5799 to discuss how our color-coded solutions can enhance your facility’s food safety program.