Industrial hose failures can result in catastrophic consequences—equipment damage, costly downtime, safety incidents, and significant liability exposure. For companies across the oil and gas, chemical processing, and manufacturing sectors, implementing a comprehensive OnGuard asset management strategy isn’t just good practice; it’s business-critical. Hose safety programs provide the framework for transforming reactive maintenance into a proactive system that protects your operations, personnel, and bottom line.

Understanding the Critical Need for Hose Safety Management

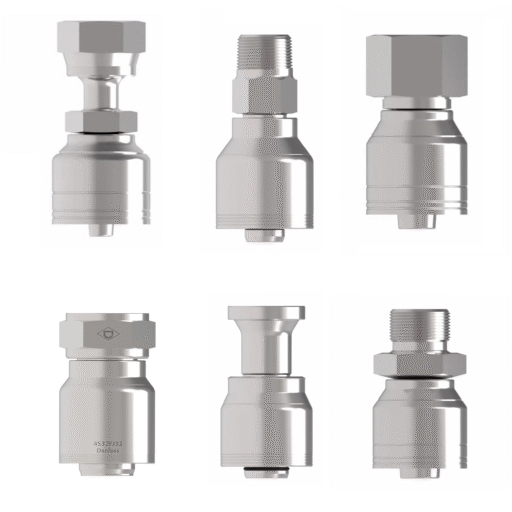

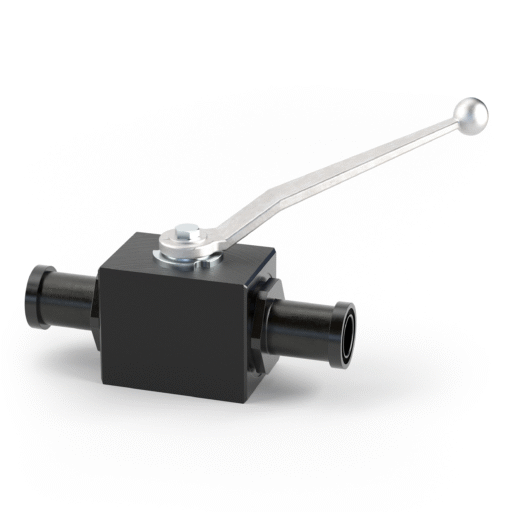

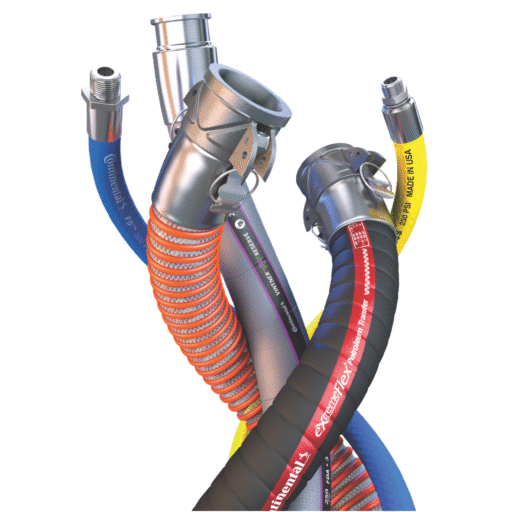

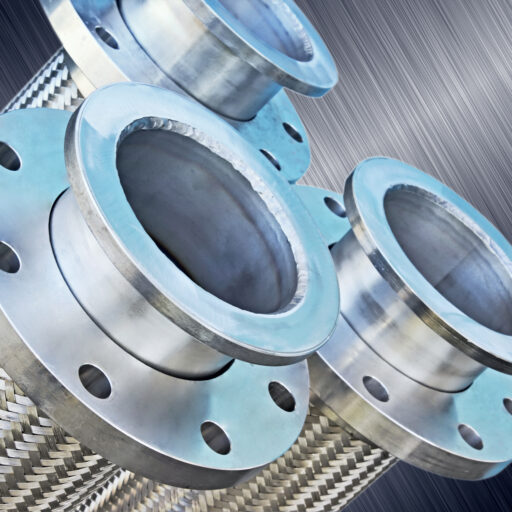

Industrial hoses operate under extreme conditions, handling everything from high-pressure hydraulic fluids to corrosive chemicals and steam. These components are often the weakest link in complex systems, yet they’re frequently overlooked in preventative maintenance programs until failure occurs. The consequences of hose safety failures extend far beyond simple replacement costs.

When hoses fail unexpectedly, the immediate risks include potential injury to personnel, environmental contamination, and equipment damage. The indirect costs—production downtime, emergency repairs, regulatory compliance issues, and liability reduction challenges—often dwarf the initial replacement expense. A single catastrophic hose failure can result in hundreds of thousands of dollars in losses and create long-term operational challenges.

Effective hose safety programs recognize that prevention costs significantly less than reaction. By implementing systematic tracking, testing, and replacement protocols through OnGuard asset management, companies can virtually eliminate unexpected hose failures while optimizing replacement schedules and inventory management.

The OnGuard Asset Management Solution for Industrial Operations

OnGuard asset management represents a comprehensive approach to hose lifecycle management that addresses every aspect of industrial hose operations. This preventative maintenance system transforms traditional maintenance approaches by providing complete visibility into hose performance, condition, and replacement needs while achieving significant liability reduction.

The OnGuard asset management program centers on five core principles: Train, Audit, Test, Tag, and Track. Each element works together to create a robust hose safety framework that protects both personnel and equipment while reducing operational costs and liability reduction exposure.

Training: Building Hose Safety Expertise

Training ensures that personnel understand proper hose selection, installation, and handling procedures. Many hose safety failures result from improper installation or handling rather than product defects. Comprehensive OnGuard asset management training programs cover hose specifications, pressure ratings, chemical compatibility, and safe handling practices.

Auditing: Proactive Hose Safety Inspections

Regular auditing identifies potential issues before they become critical failures. Systematic preventative maintenance inspections reveal wear patterns, damage, and approaching end-of-life conditions. These hose safety audits provide valuable data for optimizing replacement schedules and identifying system improvements.

Testing: Validating Hose Safety Performance

Testing validates hose integrity and performance under actual operating conditions. Hydrostatic testing, visual inspections, and other preventative maintenance evaluation methods confirm that hoses meet hose safety requirements and perform reliably in demanding applications.

Tagging: Essential OnGuard Asset Management Tracking

Tagging provides unique identification for each hose assembly, enabling precise OnGuard asset management tracking. Metal tags with unique identifiers resist harsh industrial environments while providing permanent identification throughout the hose lifecycle for optimal liability reduction.

Tracking: Comprehensive Preventative Maintenance Records

Tracking maintains comprehensive records of hose performance, maintenance, and replacement history. This OnGuard asset management data enables preventative maintenance strategies and provides valuable insights for optimizing operations while supporting liability reduction initiatives.

Implementing Preventative Maintenance Strategies with OnGuard

Successful preventative maintenance programs require systematic approaches that address the unique challenges of industrial hose safety applications. OnGuard asset management provides the framework for developing these strategies while ensuring consistent implementation across all operations.

The foundation of effective preventative maintenance lies in understanding hose applications and operating conditions. Different applications place varying demands on hose assemblies—chemical compatibility, pressure requirements, temperature extremes, and environmental factors all influence hose safety performance and lifespan.

Establishing baseline performance data through OnGuard asset management enables accurate prediction of replacement needs. By tracking hose safety performance under actual operating conditions, preventative maintenance teams can identify patterns and optimize replacement schedules. This approach prevents premature replacements while ensuring hoses are retired before failure occurs.

Regular hose safety inspection protocols identify emerging issues before they compromise safety or operations. Systematic visual inspections, pressure testing, and condition assessments provide early warning of potential problems. These preventative maintenance inspections should follow established OnGuard asset management procedures and document findings for trend analysis.

Replacement scheduling based on actual OnGuard asset management performance data optimizes inventory management and reduces emergency situations. Rather than arbitrary replacement intervals, data-driven preventative maintenance approaches ensure hoses are replaced at optimal times—maximizing service life while maintaining hose safety margins.

Achieving Significant Liability Reduction Through Proactive Management

Industrial operations face increasing liability reduction challenges from safety incidents, environmental releases, and regulatory compliance failures. Hose safety failures can trigger any or all of these liability scenarios, making OnGuard asset management a critical risk mitigation strategy.

OnGuard asset management dramatically reduces liability exposure through systematic documentation and preventative maintenance. Complete records demonstrate due diligence and responsible stewardship, critical factors in liability reduction. When companies can document comprehensive hose safety programs and proactive safety measures, they’re better positioned to defend against liability claims.

Regulatory compliance requirements continue to expand across industries, particularly in chemical processing, oil and gas, and manufacturing sectors. OnGuard asset management programs ensure companies maintain the documentation and preventative maintenance records required for regulatory compliance. This proactive hose safety approach prevents citations and fines while demonstrating commitment to safety and environmental protection.

Insurance considerations increasingly factor preventative maintenance programs into risk assessments and premium calculations. Companies with documented OnGuard asset management programs often qualify for reduced premiums and better coverage terms. The investment in hose safety management frequently pays for itself through liability reduction and insurance savings alone.

Building a Culture of Hose Safety and Accountability

Successful hose safety management programs extend beyond technical systems to create organizational cultures that prioritize safety and accountability. OnGuard asset management provides the tools and framework for building these cultures while ensuring consistent preventative maintenance implementation across all levels of the organization.

Personnel training programs ensure everyone understands their role in hose safety management. From operators who handle hoses daily to maintenance technicians who perform preventative maintenance inspections, comprehensive OnGuard asset management training creates shared understanding and accountability. Regular refresher training reinforces best practices and introduces new procedures or technologies.

Clear hose safety procedures and protocols eliminate ambiguity and ensure consistent preventative maintenance practices across shifts and locations. Written procedures should cover everything from hose selection and installation to inspection protocols and replacement criteria. These OnGuard asset management procedures provide the foundation for accountability and continuous improvement.

Performance metrics track hose safety program effectiveness and identify opportunities for preventative maintenance improvement. Key performance indicators might include hose failure rates, maintenance costs, downtime incidents, and safety metrics. Regular review of these OnGuard asset management metrics enables continuous optimization and demonstrates program value for liability reduction.

Maximizing Return on Investment with OnGuard Asset Management

OnGuard asset management programs deliver measurable returns through multiple channels—reduced downtime, lower preventative maintenance costs, improved hose safety performance, and enhanced operational efficiency. Understanding these benefits helps justify program investment and ensures maximum liability reduction value realization.

Downtime reduction represents one of the most significant benefits of proactive hose safety management. Unexpected hose failures often require immediate shutdown of entire systems or production lines. The cost of this downtime typically far exceeds the cost of the failed hose itself. By preventing unexpected failures, OnGuard asset management programs virtually eliminate hose-related downtime.

Preventative maintenance cost optimization results from better planning and scheduling of maintenance activities. Rather than emergency repairs and rush deliveries, proactive hose safety programs enable scheduled maintenance during planned downtime. This OnGuard asset management approach reduces labor costs, eliminates premium pricing for emergency services, and optimizes inventory management.

Extended hose life through proper preventative maintenance management reduces replacement costs and inventory requirements. When hoses are properly selected, installed, and maintained through OnGuard asset management, they consistently achieve or exceed their design life. This hose safety optimization reduces the total cost of ownership while maintaining safety and performance standards.

Best Practices for OnGuard Asset Management Implementation

Implementing OnGuard asset management successfully requires following proven best practices that ensure hose safety program effectiveness and liability reduction. These preventative maintenance strategies have been refined through years of experience across diverse industrial applications.

Start with a comprehensive hose safety audit to establish baseline conditions and identify immediate improvement opportunities. This initial OnGuard asset management assessment provides the foundation for developing customized preventative maintenance programs that address specific operational challenges and liability reduction needs.

Develop standardized hose safety procedures that align with OnGuard asset management protocols while meeting industry regulations and company policies. These preventative maintenance procedures should be clear, actionable, and consistently applied across all operations to ensure maximum liability reduction benefits.

Invest in proper training for all personnel involved in hose safety operations. OnGuard asset management success depends on knowledgeable personnel who understand preventative maintenance principles and can implement them effectively. Regular training updates ensure continued program effectiveness and liability reduction.

Frequently Asked Questions About OnGuard Asset Management

What is OnGuard asset management and how does it improve hose safety?

OnGuard asset management is a comprehensive hose lifecycle management system that implements five core principles: Train, Audit, Test, Tag, and Track. This preventative maintenance approach transforms reactive maintenance into proactive hose safety management, reducing unexpected failures and achieving significant liability reduction through systematic documentation and monitoring.

How quickly can OnGuard asset management reduce our maintenance costs?

Most companies implementing OnGuard asset management see immediate preventative maintenance cost reductions within 3-6 months. Hose safety improvements through proactive monitoring eliminate emergency repairs and premium replacement costs. The liability reduction benefits compound over time as comprehensive documentation protects against claims and insurance premiums decrease.

What training is required for OnGuard asset management implementation?

OnGuard asset management training covers proper hose selection, installation techniques, inspection procedures, and safety protocols. Hose safety training programs are customized for different roles—operators, maintenance technicians, and supervisors receive role-specific preventative maintenance instruction. Training duration typically ranges from 4-8 hours depending on complexity and existing knowledge levels.

How does OnGuard asset management help with regulatory compliance?

OnGuard asset management maintains comprehensive documentation required for regulatory compliance across chemical processing, oil and gas, and manufacturing industries. The system tracks preventative maintenance activities, inspection results, and replacement history, providing auditable records that demonstrate hose safety compliance and support liability reduction efforts.

Can OnGuard asset management integrate with existing maintenance systems?

Yes, OnGuard asset management integrates seamlessly with most existing preventative maintenance systems and CMMS platforms. The hose safety data and tracking information can be exported or shared with existing systems, ensuring comprehensive liability reduction documentation while maintaining operational continuity.

What is the typical ROI for OnGuard asset management programs?

OnGuard asset management typically delivers 3:1 to 5:1 ROI within the first year through reduced downtime, lower preventative maintenance costs, and liability reduction. Hose safety improvements eliminate emergency repairs, optimize inventory management, and reduce insurance premiums. Many companies recover their investment within 6-12 months.

How often should hoses be inspected under OnGuard asset management?

OnGuard asset management inspection frequency depends on application criticality, operating conditions, and regulatory requirements. Critical hose safety applications may require monthly inspections, while standard applications typically need quarterly or semi-annual preventative maintenance inspections. The system tracks performance data to optimize inspection intervals for liability reduction.

What documentation does OnGuard asset management provide for liability protection?

OnGuard asset management provides comprehensive liability reduction documentation including installation records, inspection reports, test results, maintenance history, and replacement schedules. This hose safety documentation demonstrates due diligence and proactive preventative maintenance, critical factors in defending against liability claims and regulatory investigations.

How does OnGuard asset management handle emergency situations?

OnGuard asset management includes emergency response protocols that prioritize hose safety and liability reduction. The system maintains critical spare inventory, provides 24/7 technical support, and includes rapid response procedures for emergency replacements. Preventative maintenance data helps predict and prevent most emergency situations.

What industries benefit most from OnGuard asset management?

OnGuard asset management benefits any industry using industrial hoses, particularly chemicals and related products, oil and gas exploration and services, and industrial machinery and equipment sectors. Hose safety programs are especially valuable in high-pressure, high-temperature, or chemically aggressive applications where preventative maintenance and liability reduction are critical.

Conclusion: The Strategic Advantage of Proactive Hose Safety Management

Implementing OnGuard asset management represents a strategic investment in operational excellence, hose safety performance, and liability reduction. Companies that adopt comprehensive preventative maintenance programs position themselves for sustained competitive advantage through reduced costs, improved reliability, and enhanced safety performance.

The transformation from reactive to proactive hose safety management requires commitment and systematic implementation, but the benefits far exceed the investment. Lower operating costs, reduced liability reduction exposure, improved safety performance, and enhanced operational reliability create lasting value for organizations across all industries.

In today’s competitive environment, companies cannot afford the costs and risks associated with reactive maintenance approaches. OnGuard asset management provides the tools, framework, and expertise needed to implement world-class hose safety programs that protect personnel, equipment, and profitability while positioning organizations for long-term success through effective preventative maintenance and liability reduction strategies.

Start your journey toward proactive hose safety management today. Contact Foster Hose & Fittings at 1-800-966-8111 to learn how OnGuard asset management can transform your operations while reducing costs and liability exposure through comprehensive preventative maintenance programs.

Ready to implement OnGuard asset management for your facility? Our experts at Foster Hose & Fittings specialize in hose safety solutions, preventative maintenance programs, and liability reduction strategies. Visit www.fosterhose.com or call (314) 947-5799 for your free consultation.