In the demanding world of chemical processing, equipment failure isn’t just costly—it can be catastrophic. When handling aggressive chemicals, corrosive substances, and high-purity materials, standard hose systems simply can’t deliver the reliability and safety your operations require. This is where PTFE chemical hose systems emerge as the gold standard, offering unmatched chemical resistance and performance that keeps your processes running safely and efficiently.

Understanding PTFE Chemical Hose Technology

PTFE (polytetrafluoroethylene) represents one of the most chemically inert materials available for industrial applications. Often known by the brand name Teflon™, PTFE chemical hose provides exceptional resistance to virtually all chemicals, acids, bases, and solvents encountered in chemical processing facilities. This remarkable chemical resistance stems from the unique molecular structure of PTFE, which creates an almost impenetrable barrier against chemical attack.

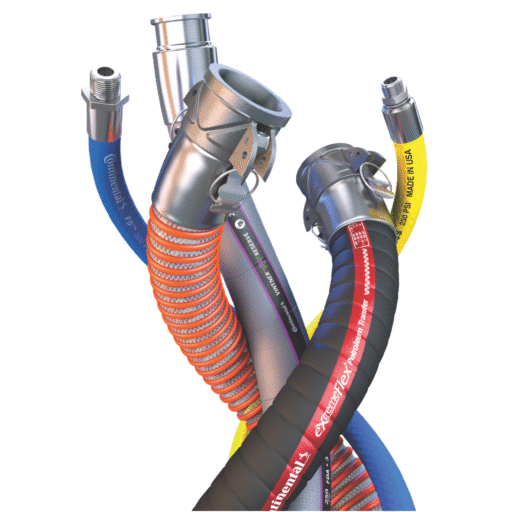

At Foster Hose & Fittings, our TUFLUOR® PTFE chemical hose assemblies are engineered specifically for the most challenging chemical processing applications. These systems feature PTFE inner tubes that maintain their integrity even when exposed to highly aggressive chemicals at elevated temperatures and pressures.

Superior Chemical Resistance Across Applications

The chemical resistance of PTFE hose systems extends far beyond what traditional rubber or plastic hoses can achieve. While standard hoses may degrade, swell, or fail when exposed to certain chemicals, PTFE maintains its structural integrity across an impressive range of substances.

Our premium PTFE chemical hose handles everything from concentrated acids and caustic solutions to organic solvents and specialty chemicals. This broad chemical compatibility means you can use the same hose system for multiple applications, reducing inventory complexity and ensuring consistent performance across your facility.

The blue EPDM cover on our TUFLUOR® PTFE hose provides additional protection while maintaining flexibility and ease of handling. This outer cover protects the PTFE core from physical damage while providing visual identification for your chemical handling systems.

High Purity Transfer Applications

High purity transfer operations demand absolute cleanliness and contamination prevention. PTFE chemical hose excels in these applications because its smooth, non-stick surface prevents product buildup and contamination. The inert nature of PTFE means it won’t leach additives, plasticizers, or other contaminants into your process streams.

For pharmaceutical manufacturing, biotechnology processes, and semiconductor fabrication, maintaining product purity is critical. Our PTFE hose systems provide the clean transfer capabilities these industries require, with full flow paths that eliminate dead zones where contaminants could accumulate.

The permanent crimp end connections on our assemblies ensure leak-free operation that maintains system integrity throughout your high purity transfer processes. Each assembly undergoes rigorous testing to verify performance before delivery, giving you confidence in your critical applications.

Exceptional Temperature Stability

Temperature stability sets PTFE chemical hose apart from other chemical transfer solutions. While standard hoses may become brittle at low temperatures or degrade at high temperatures, PTFE maintains its flexibility and performance across an impressive temperature range of -40°F to +302°F.

This temperature stability proves especially valuable in chemical processing operations that involve heating, cooling, or temperature cycling. Steam-heated reactors, cryogenic cooling systems, and thermal processing equipment all benefit from PTFE’s ability to maintain performance regardless of temperature fluctuations.

The stainless steel helix reinforcement in our TUFLUOR® systems provides structural support while allowing the hose to flex and bend without kinking. This combination of temperature stability and mechanical flexibility ensures reliable operation even in challenging installation configurations.

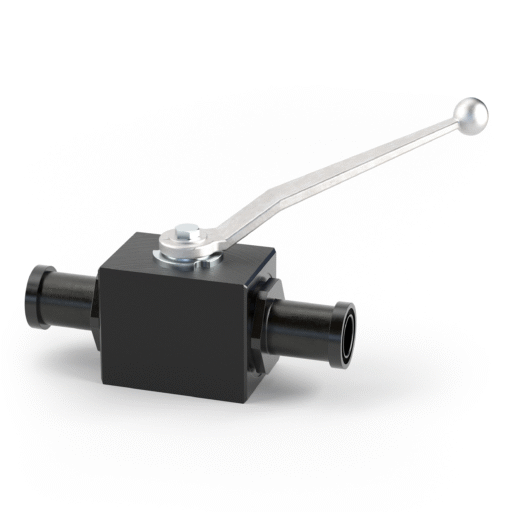

Enhanced Safety Through Proper Design

Chemical processing safety starts with proper equipment selection. PTFE chemical hose systems provide multiple safety advantages over alternative materials. The chemical resistance prevents unexpected failures that could lead to spills, exposures, or contamination incidents. The increased bend radius design reduces stress concentrations that could cause premature failure.

Our PFA/PTFE encapsulated couplings extend the chemical resistance through the entire assembly, ensuring that aggressive chemicals never contact metal surfaces that could corrode or contaminate the process stream. This full-path protection provides peace of mind in critical applications where failure isn’t an option.

The permanent crimp collar design eliminates potential leak points while providing a secure connection that won’t work loose under pressure or thermal cycling. Every assembly is pressure tested before shipment to verify integrity and performance.

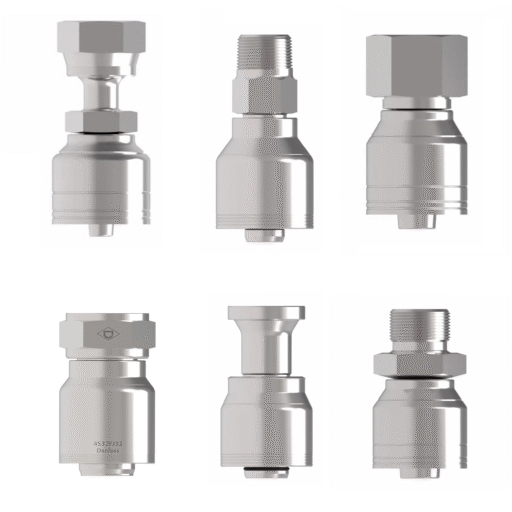

Specialized Coupling Solutions

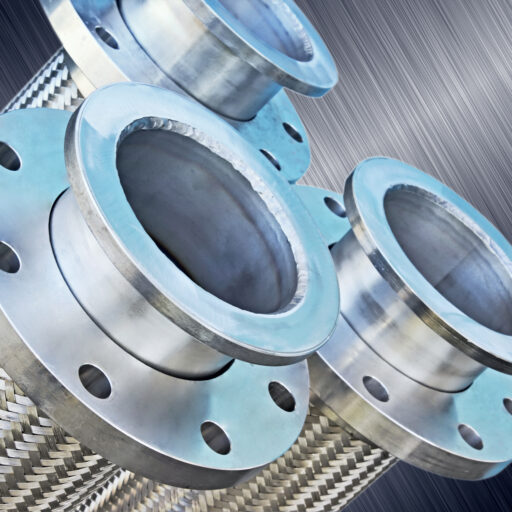

The effectiveness of any PTFE chemical hose system depends heavily on the quality of its end connections. Standard metal couplings can become the weak link in chemical resistance, potentially corroding or contaminating the process stream. Our specialized coupling solutions address these challenges with advanced designs that maintain chemical resistance throughout the entire flow path.

PFA/PTFE encapsulated couplings feature a complete fluoropolymer lining that provides the same chemical resistance as the hose itself. This ensures that aggressive chemicals never contact metal surfaces, preventing corrosion and contamination while extending service life.

For applications requiring standard connection types, our stainless steel couplings provide excellent corrosion resistance while maintaining compatibility with existing piping systems. The combination of high-quality stainless steel and precision manufacturing ensures reliable, leak-free connections that stand up to demanding chemical processing environments.

Applications Across Chemical Processing Industries

PTFE chemical hose systems serve critical functions across diverse chemical processing applications. In petrochemical facilities, these hoses handle everything from corrosive catalysts to high-purity intermediates. The chemical resistance and temperature stability prove essential for processes involving aggressive chemicals at elevated temperatures.

Pharmaceutical manufacturing relies on PTFE systems for transferring active pharmaceutical ingredients, cleaning solvents, and process chemicals where contamination could compromise product quality or patient safety. The smooth interior surface and chemical inertness ensure product integrity throughout the transfer process.

Specialty chemical production often involves unique or proprietary formulations that could attack conventional hose materials. PTFE’s broad chemical resistance provides confidence that even unknown or untested chemical combinations won’t cause unexpected failures.

Installation and Maintenance Considerations

Proper installation maximizes the performance and service life of PTFE chemical hose systems. The increased bend radius design requires careful attention to routing and support to prevent stress concentrations. Our technical team provides guidance on proper installation practices that ensure optimal performance.

Maintenance requirements for PTFE systems are typically minimal compared to other hose types. The chemical resistance means less frequent replacement due to chemical attack, while the smooth interior surface resists buildup that could restrict flow or harbor contaminants. Regular visual inspections and pressure testing help identify any issues before they become problems.

Cleaning procedures should account for the specific chemicals being handled and any potential reactions between different process streams. The chemical resistance of PTFE allows for aggressive cleaning protocols when necessary, but proper procedures ensure cleaning agents don’t interfere with subsequent processes.

Quality Assurance and Testing

Every PTFE chemical hose assembly from Foster Hose & Fittings undergoes comprehensive testing before shipment. Pressure testing verifies the integrity of the assembly and ensures it can handle specified operating pressures with appropriate safety margins. Visual inspection confirms proper assembly and identifies any potential issues.

Material certifications provide traceability and verify that all components meet specified requirements. This documentation supports quality management systems and regulatory compliance requirements common in chemical processing facilities.

Our commitment to quality extends beyond individual assemblies to encompass the entire manufacturing process. From raw material selection through final testing, every step is controlled and monitored to ensure consistent performance.

Custom Solutions for Unique Applications

Standard PTFE chemical hose assemblies handle most applications, but some processes require custom solutions. Our engineering team works with customers to develop specialized assemblies that meet unique requirements for pressure, temperature, chemical compatibility, or configuration.

Custom length assemblies eliminate unnecessary joints that could leak or restrict flow. Special end configurations accommodate unique connection requirements or space constraints. Multiple-line assemblies reduce installation complexity while maintaining individual line integrity.

The ability to customize assemblies ensures optimal performance in your specific application while maintaining the chemical resistance and reliability that make PTFE the preferred choice for demanding chemical processing operations.

Cost-Effectiveness Through Reliability

While PTFE chemical hose systems typically require higher initial investment than standard alternatives, their superior performance and extended service life often result in lower total cost of ownership. Reduced replacement frequency, minimal maintenance requirements, and improved safety all contribute to long-term value.

Preventing even one chemical spill or contamination incident can save far more than the cost difference between PTFE and standard hose systems. The reliability and safety benefits provide additional value that extends beyond simple cost comparisons.

Our technical expertise helps customers select the right PTFE system for their specific application, ensuring optimal performance while avoiding over-specification that could increase costs unnecessarily.

Frequently Asked Questions

Q: How do I determine if PTFE chemical hose is necessary for my application?

Consider PTFE for applications involving aggressive chemicals, high temperatures, high purity requirements, or where standard hoses have experienced premature failure. Our technical team can evaluate your specific chemicals and operating conditions to recommend the best solution.

Q: What’s the difference between PTFE and PFA in chemical hose applications?

Both materials offer excellent chemical resistance, but PFA provides slightly better flexibility and transparency. PTFE offers broader chemical compatibility and higher temperature capability. The choice depends on your specific application requirements.

Q: Can PTFE chemical hose handle vacuum applications?

Yes, our PTFE hose assemblies include reinforcement designed to handle both positive pressure and vacuum conditions. The stainless steel helix provides structural support that prevents collapse under vacuum.

Q: How do I properly clean PTFE chemical hose between different chemicals?

Cleaning procedures depend on the chemicals involved and potential reactions. The chemical resistance of PTFE allows aggressive cleaning when necessary, but always verify compatibility between cleaning agents and subsequent process chemicals.

Q: What pressure ratings are available for PTFE chemical hose?

Our standard TUFLUOR® systems are rated for 250 PSI in sizes 1/2″ through 3″, with 185 PSI rating for 4″ diameter. Higher pressure ratings may be available for specific applications through custom design.

Q: How long do PTFE chemical hose assemblies typically last?

Service life depends on operating conditions, but PTFE systems often outlast standard alternatives by significant margins due to their chemical resistance and temperature stability. Many installations provide years of reliable service with minimal maintenance.

For demanding chemical processing applications where failure isn’t an option, PTFE chemical hose systems from Foster Hose & Fittings provide the reliability, safety, and performance your operations require. Contact our technical experts at (314) 947-5799 to discuss how our premium PTFE solutions can enhance your chemical processing capabilities while ensuring safe, reliable operation.