Choosing the right FDA-compliant hose for food processing facilities is critical for maintaining safety standards and avoiding costly recalls. Whether you operate dairy plants, meat processing facilities, beverage production lines, or cosmetic manufacturing in St. Louis or nationwide, this comprehensive guide will help you select food-grade hoses that meet FDA regulations and protect your operations.

Why FDA-Compliant Hoses Are Essential for Food Safety

FDA-approved hoses prevent food contamination by meeting strict federal safety standards. When food processing hoses fail, break down, or harbor bacteria, the consequences can devastate your business:

- Product contamination leading to consumer health risks

- Spoiled inventory resulting in significant financial losses

- Production shutdowns disrupting supply chains

- FDA violations triggering fines and legal action

- Brand reputation damage affecting long-term profitability

All food processing hoses must comply with FDA’s 21 CFR 177 requirements for food contact materials—regulations that apply to every food processing facility across the United States, including St. Louis operations.

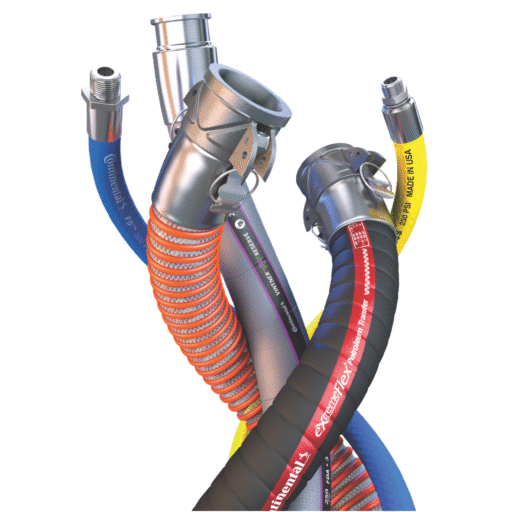

Understanding Food-Grade Hose Construction

Every component of an FDA-compliant hose serves a specific safety function:

Inner Tube (Food Contact Layer)

The inner tube directly contacts food products and must be non-reactive, non-toxic, and easy to sanitize. Common FDA-approved materials include:

- PTFE (Polytetrafluoroethylene) – Chemical resistant, non-stick surface

- UHMWPE (Ultra-High Molecular Weight Polyethylene) – Highly chemical resistant

- EPDM rubber – Temperature resistant, flexible

- Nitrile rubber – Oil and chemical resistant

Reinforcement Layer

Textile braids or steel wire provide structural strength and pressure resistance while maintaining flexibility for food processing operations.

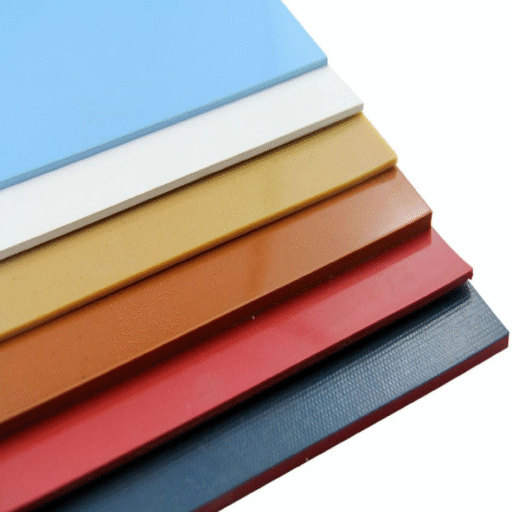

Outer Cover

Durable covers protect against washdowns, abrasion, and environmental factors common in food processing facilities.

FDA-Compliant Hose Materials by Food Processing Application

EPDM and Nitrile Rubber Hoses

Best for: General food transfer, dairy processing, juice production

- Excellent temperature resistance for hot food products

- Flexible construction for complex routing

- Durable performance in demanding food processing environments

- FDA-approved formulations available

Silicone Food-Grade Hoses

Best for: High-temperature cleaning, cosmetics, pharmaceuticals

- Superior heat resistance for steam cleaning cycles

- Taste and odor neutral properties

- Excellent flexibility at low temperatures

- FDA and USP Class VI approved options

PTFE (Teflon) Lined Hoses

Best for: Chemical processing, extreme temperatures, specialty food additives

- Outstanding chemical resistance

- Non-stick interior prevents product buildup

- Easy cleaning and sanitization

- Wide temperature range capability

UHMWPE Food Hoses

Best for: Acidic products, syrups, sauces, aggressive cleaning chemicals

- Exceptional chemical resistance

- FDA-approved for direct food contact

- Smooth interior surface for easy cleaning

- Long service life in demanding applications

PVC and Thermoplastic Food Hoses

Best for: Ambient temperature liquids, visual product monitoring

- Cost-effective solution for budget-conscious operations

- Transparent options for visual flow monitoring

- Lightweight and easy handling

- Suitable for non-aggressive food products

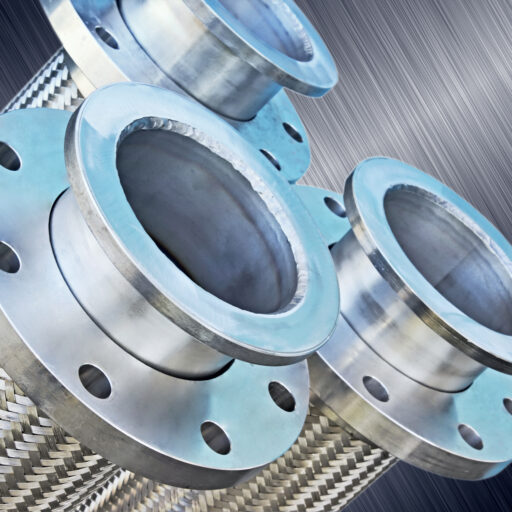

Essential Food Processing System Components

Creating a complete FDA-compliant system requires more than just the right hose:

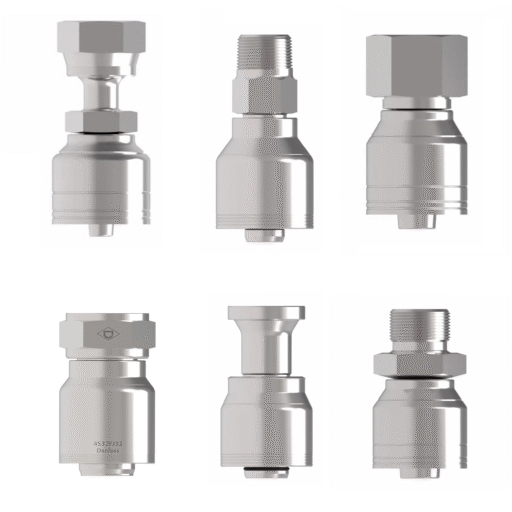

Sanitary Fittings

- 304 and 316 stainless steel construction

- Tri-clamp connections for easy assembly/disassembly

- Smooth interior surfaces preventing bacterial growth

- FDA-approved materials for all food contact surfaces

Food-Grade Gaskets and Seals

- EPDM gaskets for general food applications

- PTFE seals for chemical resistance

- Silicone gaskets for high-temperature operations

- FDA-compliant materials ensuring food safety

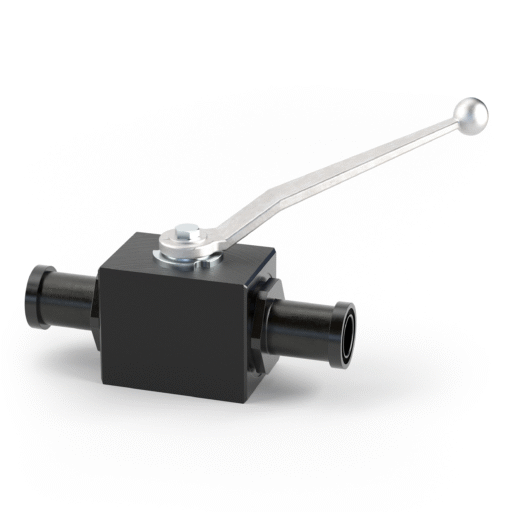

Sanitary Valves

- Butterfly valves for flow control

- Ball valves for on/off applications

- Diaphragm valves for sterile processes

- Sanitary designs meeting 3-A standards

Industry-Specific FDA Hose Applications

Dairy Processing Facilities

Dairy operations require hoses that withstand frequent steam cleaning and continuous use. Nitrile, EPDM and silicone hoses with stainless steel fittings provide optimal performance for milk, cream, and cheese processing.

Meat and Poultry Processing

These facilities need hoses resistant to fats, oils, and aggressive cleaning chemicals. Specialized rubber compounds and PTFE-lined options handle these demanding conditions.

Beverage Production

PTFE-lined hoses prevent flavor transfer and contamination in soft drink, juice, and alcoholic beverage production while maintaining product integrity.

Condiment Manufacturing

High-salt, acidic products like ketchup and mustard require UHMWPE or PTFE hoses that resist chemical attack and maintain food safety standards.

Cosmetic Manufacturing

Food-grade cosmetic facilities use silicone and PTFE hoses to prevent leaching into sensitive formulations while meeting FDA cosmetic regulations.

Best Practices for FDA-Compliant Hose Systems

Proper Material Selection

- Match hose materials to specific media (acids, oils, abrasives)

- Verify pressure and temperature ratings exceed operating conditions

- Confirm FDA compliance documentation for all components

Cleaning and Maintenance Protocols

- Use cleaning methods compatible with hose materials

- Implement Clean-in-Place (CIP) and Steam-in-Place (SIP) procedures appropriately

- Replace hoses at first signs of wear or degradation

- Maintain detailed cleaning and inspection records

Operational Safety Measures

- Implement color-coded hose systems to prevent cross-contamination

- Train staff on proper hose handling, storage, and care procedures

- Establish regular inspection and replacement schedules

- Document all maintenance activities for regulatory compliance

Choosing a Reliable FDA Hose Supplier

Partner with experienced suppliers who understand food processing requirements and provide comprehensive support for your operations.

Foster Hose & Fittings offers:

- Certified FDA-compliant hose assemblies meeting all regulatory requirements

- 3-A sanitary hose configurations for dairy and food processing

- Complete documentation packages for regulatory audits and inspections

- Ongoing maintenance support and replacement scheduling services

- Expert consultation for complex food processing applications

Our St. Louis-based team serves food processors throughout Missouri and nationwide, providing reliable, compliant hose solutions that keep your facility operating safely and efficiently.

Get Expert FDA Hose Guidance Today

Ensure your food processing facility maintains FDA compliance while optimizing operational efficiency. Contact Foster Hose & Fittings for professional consultation on your specific application requirements.

Call (314) 947-5799 or visit fosterhose.com to request a quote and speak with our food industry hose experts about your FDA-compliant hose needs.

Foster Hose & Fittings specializes in FDA-compliant hose assemblies for food processing facilities nationwide. Our certified products meet all federal regulations while providing reliable performance in demanding food production environments.