Liquip Velvet Touch MK2 Balance Assembly

The Velvet Touch MK2 Balance Assembly has been designed for use with bottom-loading arms in petrochemical-distribution depots. The MK2 features horizontal-plane swivel capability that allows 360° rotation of the bottom-loading arm and easy coverage of the width of a standard API envelope. The vertical-plane swivel allows movement 15° above and below horizontal to satisfy various coupler-height requirements while working in conjunction with twin lift-O-mat struts, which minimizes the amount of effort required to position the API coupler.

Features/Benefits

Technical

Specifications

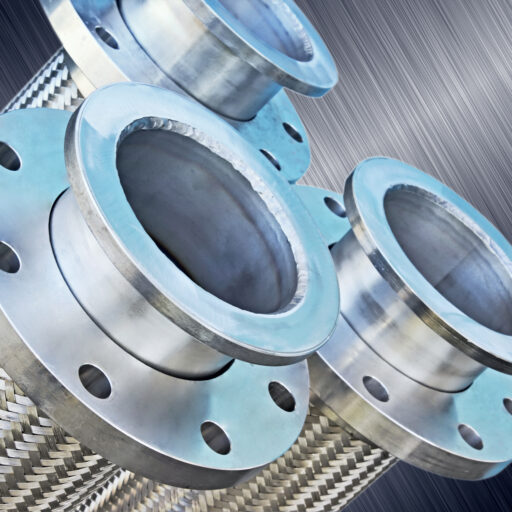

| Mounting | Base flange is 4″ ANSI 150 raised face flange. Outlet flange is 100mm (4″) TTMA pattern. |

|---|---|

| Technical Data |

|

| Working Pressure | 1,000 kPa (145 PSI) |

| Test Pressure | 1,500 kPa (218 PSI) |

| Weight | 60 kg (132lb) |

| Operating Temperature | -20° to +80°C (-4° to +176°F) for EPDM & Viton B70 grade -40° to +60°C (-40° to +140°F) for Viton GFLT grade |

| Associated Equipment | See Velvet Touch loading arm systems. |

* Note: The nature of Teflon is that it is unyielding but easily scratched; therefore the slightest damage can lead to weeps particularly where clamping force is provided by a spring which is necessarily limited in force. However the use of Teflon cannot be avoided because of its outstanding chemical resistance. Liquip guarantee the sealing of all new products and test all production prior to dispatch. Following installation of the equipment by the Purchaser it is essential that the valve be kept perfectly clean, any test liquids be perfectly clean and no tools be allowed to touch the Teflon seals. It is not uncommon for valves to exhibit small weeps once in service with commercial-quality liquids.